Product design for zero waste is a key element of the circular economy's business model; “service-design-37” (CC BY 2.0) by tobiastoft

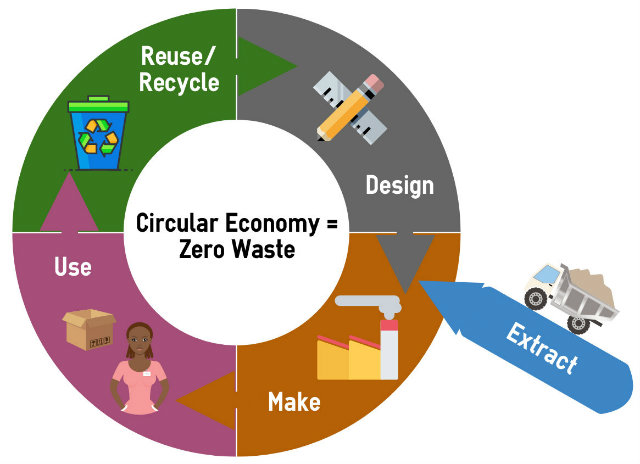

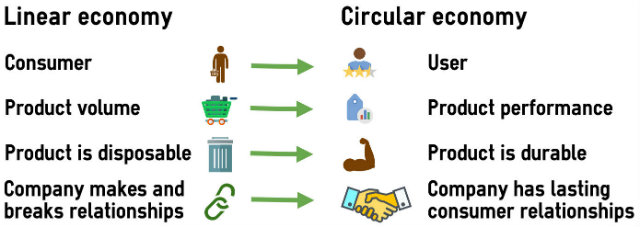

The circular economy uses a product's materials for as long as possible to achieve zero waste. This business model differs from the popular linear economy where consumers buy, use, and throw away products.

The linear economy looks like this:

The circular economy looks like this:

This article is the first in a new series on the circular economy. Here we discuss how the circular economy works. The video below provides a synopsis.

Product design is key to the circular economy's business model. Designers should create products that both last a long time and are reusable or recyclable. The Royal Society for the encouragement of Arts, Manufactures and Commerce (RSA) supports four circular design models.

Designing for longevity. Consumers can use these products for as long as possible before disposal. These products must come apart easily for repair and upgrade.

Designing for longevity. Consumers can use these products for as long as possible before disposal. These products must come apart easily for repair and upgrade.

Designing for leasing/service. The provider keeps ownership of the product and oversees maintenance. This concept is like designing for longevity, but it would typically be for more expensive products.

Designing for leasing/service. The provider keeps ownership of the product and oversees maintenance. This concept is like designing for longevity, but it would typically be for more expensive products.

Designing for reuse in manufacture. Designers should create products that disassemble easily to allow reuse of parts in new products. Consumers must return items to the manufacturer for this design to work.

Designing for reuse in manufacture. Designers should create products that disassemble easily to allow reuse of parts in new products. Consumers must return items to the manufacturer for this design to work.

Designing for material recovery. This design model applies to products meant for the consumer to toss out (such as packaging). Designers should make such products recyclable to help achieve zero waste.

Designing for material recovery. This design model applies to products meant for the consumer to toss out (such as packaging). Designers should make such products recyclable to help achieve zero waste.

Read more about these circular design models and the challenges with deploying them.

"Waste" materials in the circular economy's business model are remanufactured to be the main source of "raw" materials. Thus, products drastically reduce their use of natural resources. Product design goes into extracting as few natural resources as possible.

This change is important because the world used about 65 billion tonnes of raw material in 2010 alone. The world will grow its raw material use further to 82 billion tonnes in 2020.

Source — Ellen MacArthur Foundation report Towards the Circular Economy Volume I

Many factories use wasteful processes under the linear business model, as seen by the numbers below.

Manufacturing products for a circular economy means cutting back on resources such as materials, energy, and water. Some ways for manufacturing to move toward the circular economy include:

Using less hazardous chemicals. Companies can help the environment and lower costs to remediate hazardous waste produced in the manufacturing process1.

Using less hazardous chemicals. Companies can help the environment and lower costs to remediate hazardous waste produced in the manufacturing process1.

Operating closed loop manufacturing. Companies can use recycled materials in their processes, which moves toward zero waste and saves money on material purchases1.

Operating closed loop manufacturing. Companies can use recycled materials in their processes, which moves toward zero waste and saves money on material purchases1.

Minimizing, reusing, and selling water. Factories should first find ways to reduce water use. They can also evaluate ways to clean and put the water back into the system, and sell some types of sludge for other processes1.

Minimizing, reusing, and selling water. Factories should first find ways to reduce water use. They can also evaluate ways to clean and put the water back into the system, and sell some types of sludge for other processes1.

Improving chilling units to use less energy. This step saves energy and money because up to half of a plant's energy costs are from chilling units, which provide cool water for industrial processes3.

Improving chilling units to use less energy. This step saves energy and money because up to half of a plant's energy costs are from chilling units, which provide cool water for industrial processes3.

Sources

Repairing, repurposing, and donating are traditional ways to use a product for as long as possible. The circular economy pushes the concept further by recategorizing a consumer as a user. A consumer buys a product and is responsible for its repair. A user takes the product and the company manages its upkeep. Thus, durable products are leased or shared1.

The circular economy shifts the business model to services, as seen below2.

Sources

Recycling, reusing, or remanufacturing products would return their materials to the economy by1:

Product design connects strongly with each of these actions, particularly remanufacturing. For example, companies could reduce phone remanufacturing costs by half if designers made them easier to take apart2.

Sources

Sustainability's triple bottom line integrates social, environmental, and financial factors (also known as people, planet, and profit) to achieve a balance. Below we look at how the circular economy promotes each part of the triple bottom line. Learn more about the triple bottom line here.

The social benefits of the circular economy are:

Sources

The world needs to start the shift from the linear to the circular economy because:

The environmental benefits of the circular economy are:

Replacement of a quarter of the natural resources used for construction by recycling construction and demolition waste1. Countries could also limit the amount of raw materials they import.

Replacement of a quarter of the natural resources used for construction by recycling construction and demolition waste1. Countries could also limit the amount of raw materials they import.

Use of about 85% less energy through remanufacturing. Remanufacturing waste materials worldwide would save about the same amount of energy as is generated from five nuclear power plants.

Use of about 85% less energy through remanufacturing. Remanufacturing waste materials worldwide would save about the same amount of energy as is generated from five nuclear power plants.

Prevention of about 800,000 tonnes of carbon emissions annually instead of manufacturing from raw materials2. This reduction equals about 1% of emissions from cars.

Prevention of about 800,000 tonnes of carbon emissions annually instead of manufacturing from raw materials2. This reduction equals about 1% of emissions from cars.

Sources

Economic benefits of the circular economy include:

Sources